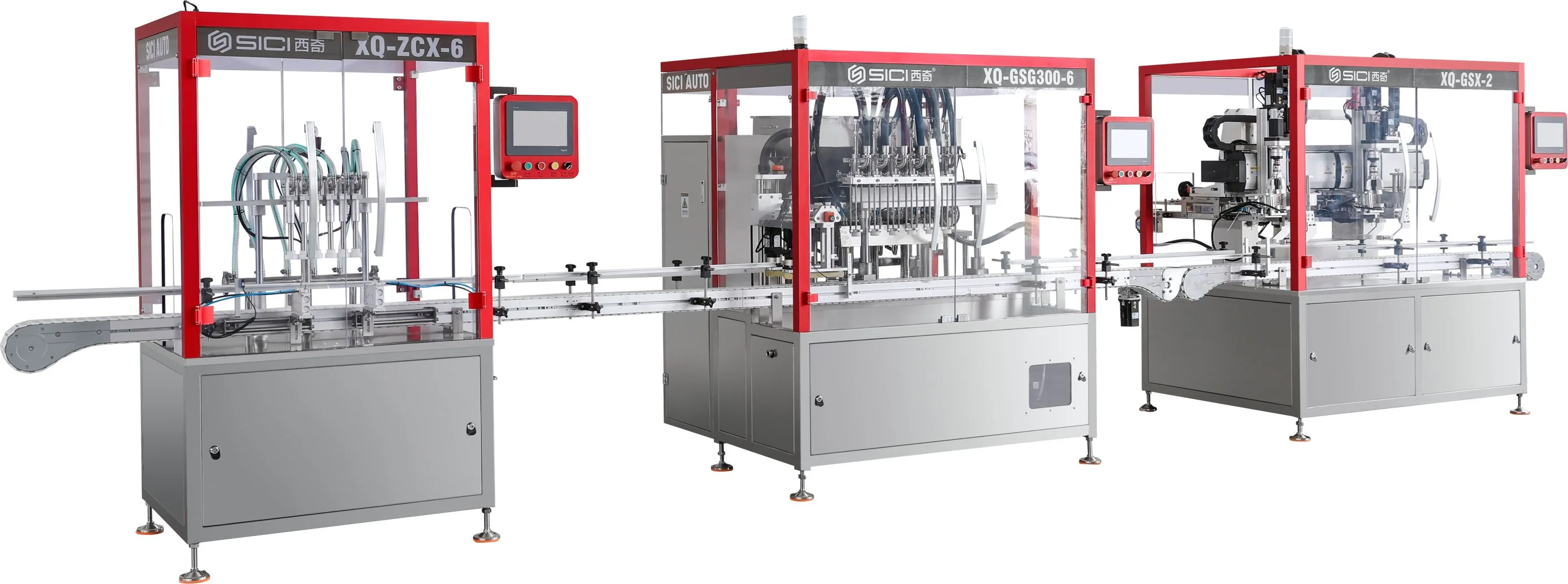

In today's fast-paced manufacturing environment, efficiency and precision are paramount. This is particularly true in the packaging industry, where the ability to quickly and accurately fill and seal products can mean the difference between success and failure. Enter the filling and capping machine—a versatile and reliable solution designed to streamline packaging processes.

Main Characteristics and Advantages

1. One or Two Servo-Driven Capping Heads

One of the standout features of filling and capping machines is their servo-driven capping heads. These heads are powered by high-precision servo motors, which provide unparalleled control and accuracy during the capping process. Whether the machine is equipped with one or two capping heads, this feature ensures that each container is sealed tightly and consistently. The servo-driven technology also allows for easy adjustment of capping torque, enabling manufacturers to tailor the sealing process to suit different types of containers and caps.

2. Continuous Working Mode

Another key advantage of filling and capping machines is their continuous working mode. Unlike manual or semi-automatic systems, which often require stopping and starting to accommodate different stages of the packaging process, these machines can cap containers while the packing material is constantly moving. This continuous operation significantly reduces downtime and increases overall productivity.

Continuous Capping Can Improve:

Throughput: By eliminating the need to stop and start the capping process, continuous working mode allows for higher throughput rates. This is particularly beneficial for manufacturers with high-volume production needs.

Consistency: Continuous capping ensures that each container receives the same level of torque and sealing pressure, resulting in more consistent product quality.

Efficiency: With reduced downtime and increased throughput, manufacturers can achieve greater overall efficiency and cost savings.

3. Advanced Sensing and Monitoring Capabilities

Modern filling and capping machines come equipped with advanced sensing and monitoring capabilities. These features enable manufacturers to monitor the capping process in real-time, detecting any issues or inconsistencies as they arise. Sensors can detect factors such as cap torque, container position, and sealing pressure, ensuring that each step of the process meets predefined specifications.

The benefits of this advanced monitoring include:

Quality Control: Real-time monitoring allows for immediate detection and correction of any defects, ensuring that only high-quality products reach the market.

Predictive Maintenance: By tracking machine performance over time, manufacturers can identify potential issues before they lead to downtime or product defects.

Data-Driven Decision Making: Collected data can be analyzed to identify trends, optimize processes, and inform future production strategies.

4. Versatility and Flexibility

Filling and capping machines are designed to be versatile and flexible, accommodating a wide range of container sizes, shapes, and materials. This versatility is achieved through modular design and adjustable components, which allow manufacturers to quickly and easily reconfigure the machine to suit different products.

The flexibility of these machines offers several advantages:

Reduced Changeover Times: Quick and easy changeovers mean that manufacturers can switch between different product lines with minimal downtime.

Cost Savings: By reducing the need for specialized equipment for each product, manufacturers can achieve cost savings and improve overall efficiency.

Competitive Advantage: The ability to quickly adapt to new products and market demands gives manufacturers a competitive edge in today's rapidly changing market.

5. Easy Integration with Existing Lines

Another key advantage of filling and capping machines is their ease of integration with existing packaging lines. Manufacturers can choose from a range of machine configurations and options to ensure seamless integration with their existing equipment. This compatibility means that manufacturers can upgrade their packaging processes without overhauling their entire production line.

The benefits of easy integration include:

Minimized Disruption: Seamless integration means that manufacturers can upgrade their packaging processes with minimal disruption to existing operations.

Scalability: As production needs grow, manufacturers can easily add additional filling and capping machines to their line, scaling up their capacity without the need for major modifications.

Cost Efficiency: By avoiding the need for a complete overhaul of existing equipment, manufacturers can achieve cost savings and faster return on investment.

In conclusion, filling and capping machines offer a range of advantages that make them an essential component of modern packaging processes. Their servo-driven capping heads, continuous working mode, advanced sensing and monitoring capabilities, versatility, and ease of integration make them a highly effective solution for manufacturers seeking to improve efficiency, consistency, and product quality. As the packaging industry continues to evolve, filling and capping machines will play an increasingly critical role in meeting the demands of today's consumers and markets.

Comments (0)