Auto parts moulds are integral components in the automotive industry, enabling efficient production of a wide variety of car parts. These moulds, often crafted from durable materials like steel or aluminum, play a key role in shaping components with high precision, allowing manufacturers to meet the strict quality standards required in automotive production.

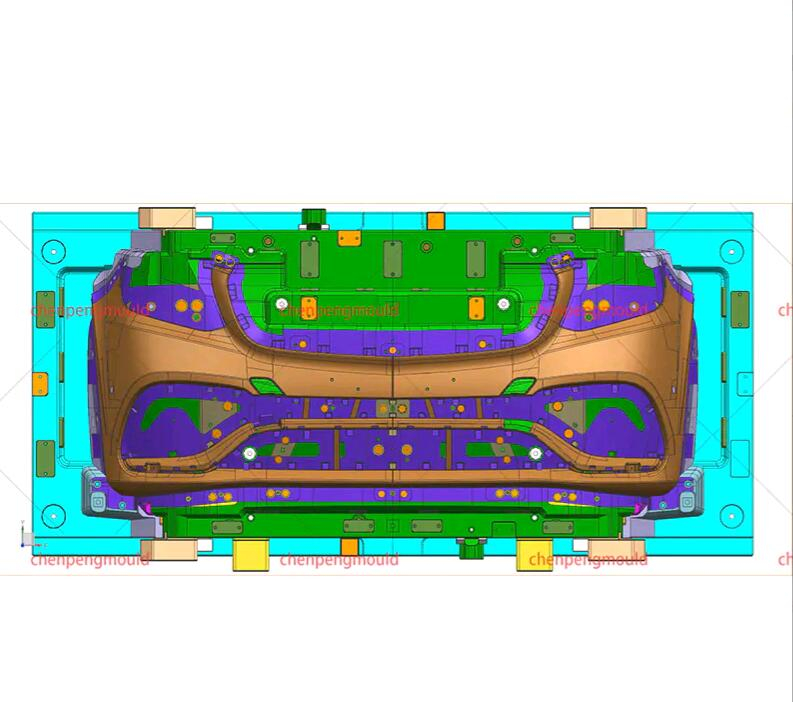

The primary function of auto parts moulds is to facilitate the mass production of parts by injecting molten materials, such as plastic, into a mould cavity. This process, known as injection moulding, allows manufacturers to create complex shapes with consistency and minimal waste. The ability to produce thousands of identical parts efficiently is particularly critical in the automotive industry, where volume and quality control are essential.

The design and construction of these moulds require significant expertise. Moulds must be engineered to withstand high pressures and temperatures without deforming or losing their shape. This is especially true for parts that need to meet strict safety standards, such as airbags or brake components. The precision and durability of the moulds directly impact the final product’s reliability and performance.

Another important aspect of auto parts moulds is their contribution to cost-effectiveness in production. By using moulds, manufacturers can achieve economies of scale, reducing the per-unit cost of parts. Additionally, the reusability of moulds makes them a long-term investment, providing value over multiple production cycles.

https://www.bumpermould.net/product/bumper-mould/no-flash-mercedesbenz-gls-maybach-front-bumper-mould.html

Why choose us?

Experience: We have had strong expertise in designing and developing automotive injection molds since 2000. Our company has developed 1000 bumper molds, including Volkswagen, Audi, Mercedes, BMW, Toyota, Ford, Skoda, etc. Moreover, we also developed higcarsbumper bumpers, like Rolls-Royce, Lamborghini I, Porsche Panam, er, an, etc.

Performance: Our bumper molds consistently deliver higher precision and quality in the molded parts compared to others.

Uniqueness ur bumper molds have unique features and innovations that set them apart. It includes advanced cooling systems, innovative design elements, and special coatings that improve durability and reduce cycle times.

Quality AssAssurancestressesss our commitment to quality assurance processes and standards that ensure the reliability and consistency of our bumper mold's output.

Comments (0)