In modern packaging industries such as pharmaceuticals, cosmetics, and daily chemicals, square and flat containers are widely used. However, labeling these shapes accurately presents unique challenges. Labels often slip, wrinkle, or misalign when applied manually or with basic equipment. This not only affects product appearance but also reduces brand credibility and compliance with industry standards. A Single Side Labeling Machine offers an effective solution to ensure precision, efficiency, and consistency in labeling.

How a Single Side Labeling Machine Works

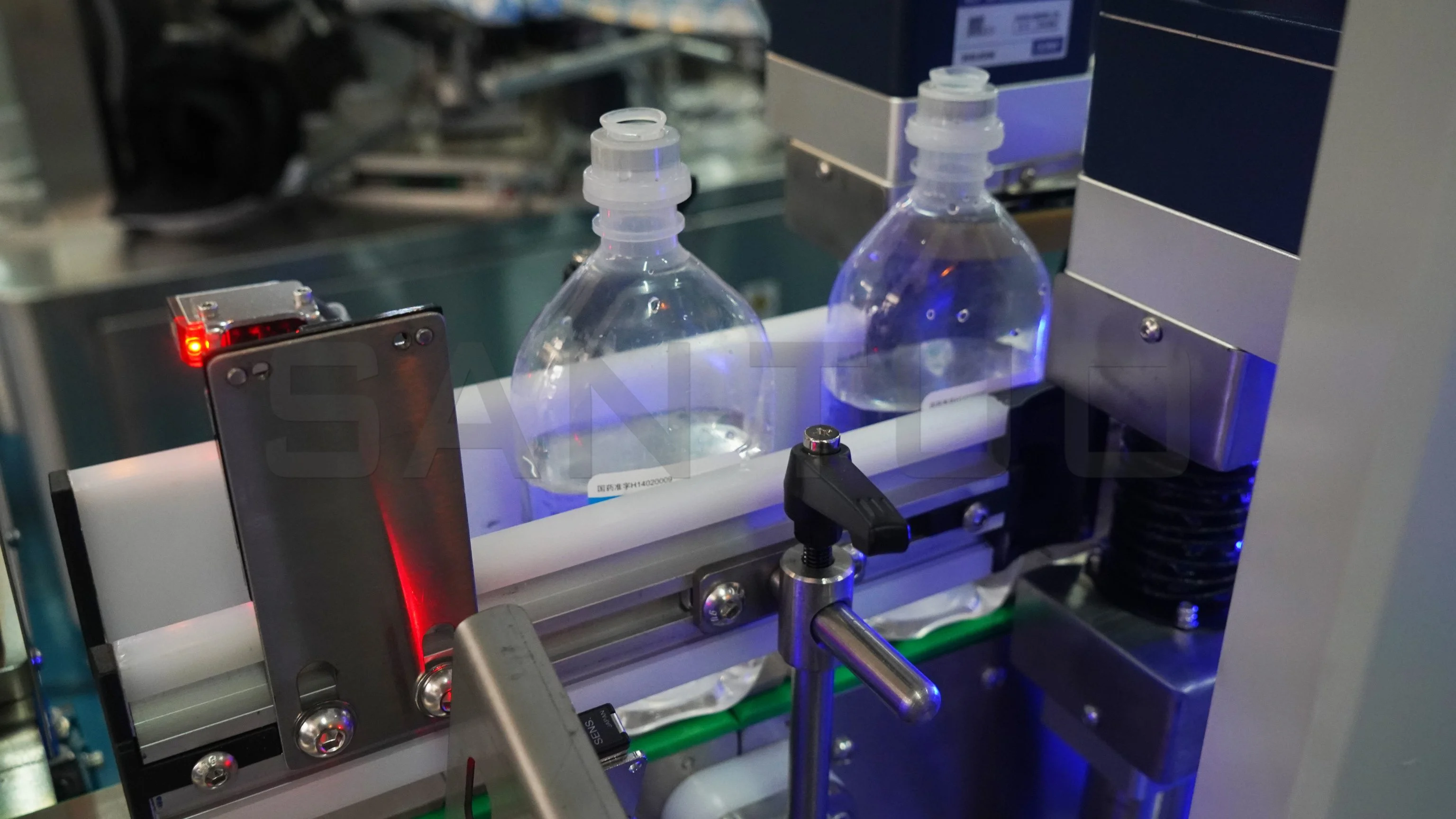

The Single Side Labeling Machine is designed with a step-by-step mechanism to guarantee accurate label placement. Products are first spaced evenly by a separating wheel. A correction belt then adjusts their orientation, ensuring proper alignment. A top stabilizer secures the containers during transportation, preventing movement. When the sensor detects a product, the label is applied precisely to the bottle body. Finally, a scraper smooths the label to eliminate bubbles or wrinkles, resulting in a clean and professional finish.

This systematic process makes the machine especially suitable for flat bottles, square containers, and boxes, such as IV bottles, hand sanitizer bottles, lipsticks, and cosmetic packaging.

Key Features and Advantages

1. Precision and Durability

The labeling drive uses an emery material active roller and adaptive rubber pressure roller. The emery surface provides strong friction for accurate label stopping, while its high wear resistance ensures long service life.

2. Flexible Orientation Correction

The double elastic chain correction strap adapts to containers with curved or irregular planes. This flexibility ensures products pass smoothly while maintaining perfect alignment for accurate labeling.

3. Stable Transmission System

The top belt uses a hinge wheel and synchronous conveying design, ensuring speed synchronization and reliable transmission, even under high-speed operation.

4. Consistent Labeling Accuracy

An elastic stabilizer design accommodates containers of varying heights without losing grip, allowing consistent product flow and precise labeling across multiple product types.

5. Compliance with GMP Standards

Constructed with high-quality stainless steel and aluminum alloy, the machine is rust-resistant, durable, and fully compliant with GMP specifications, making it ideal for pharmaceutical and high-standard industries.

Applications Across Industries

The Single Side Labeling Machine is versatile and widely applied in multiple industries:

· Pharmaceuticals: Accurate labeling of IV bottles, vials, and medical packaging ensures compliance and safety.

· Cosmetics and Daily Chemicals: Perfect for flat or square containers like hand sanitizers, lotions, and lipsticks, where brand image is critical.

· Food and Beverage: Labeling square juice bottles, flat sauce containers, or specialty packaging with consistent quality.

By improving accuracy and speed, this machine helps businesses reduce labeling errors, increase production output, and enhance packaging aesthetics.

Why Choose This Equipment

Investing in a Single Side Labeling Machine provides several long-term benefits:

· Efficiency: Automates a traditionally manual process, reducing labor costs.

· Versatility: Handles a wide range of square and flat containers with minimal adjustments.

· Quality Assurance: Ensures labels are applied consistently, avoiding misaligned or damaged labels.

· Regulatory Compliance: Meets GMP standards, essential for pharmaceutical and high-end cosmetic packaging.

For companies looking to streamline production while maintaining accuracy and professionalism, this machine offers an excellent return on investment.

Conclusion

Square and flat containers require specialized solutions for accurate and efficient labeling. A Single Side Labeling Machine combines precision engineering with durability and flexibility, making it an essential tool for industries where quality and compliance matter most. Whether in pharmaceuticals, cosmetics, or food production, this equipment enhances packaging efficiency while protecting brand reputation.

Comments (0)