Industries reliant on precision, such as printing, packaging, and paper manufacturing, find an indispensable ally in the form of a web guide system. This technology ensures meticulous alignment and seamless tracking of web content throughout the production journey. However, the pinnacle of performance is attainable only through meticulous installation and calibration. This article ventures into the intricacies of web guide system installation, elucidating best practices that foster efficiency, minimal downtime, and operational excellence for manufacturing machines.

Laying the Groundwork: Preparing for Web Guide System Installation

Embarking on the installation journey mandates a thorough prelude. Delve into system specifications, conduct a site reconnaissance, and ensure all requisites tools and components stand at the ready. Immersing oneself in the manufacturer’s guidelines and instructions proves crucial, for they harbor invaluable insights that align with the web guiding system at hand.

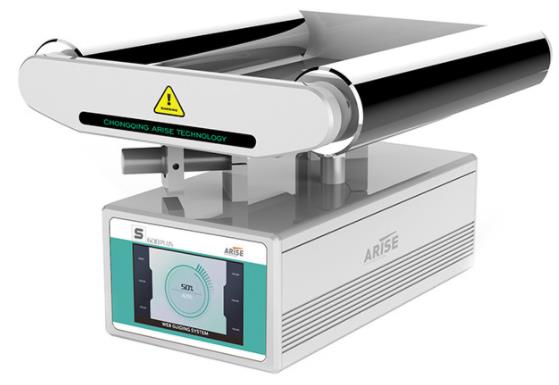

The Art of Mounting and Aligning Web Guide Systems

The foundation of the web guide system's prowess rests in its installation. Opt for a location conducive to maintenance and adjustments. The chosen mounting surface must possess the structural integrity to support the system's weight. Align with precision the manufacturer's recommendations, including mounting height, distance from neighboring equipment, and other critical specifications.

Alignment emerges as the cornerstone for accurate web tracking. Forge a parallel trajectory between the web guide system and the web path, ensuring perpendicularity to the web material's course. Precision leveling tools materialize as allies in this pursuit. Even a hair's breadth of misalignment during installation can trigger tracking predicaments, undermining the system's performance.

The Prelude to a Seamless Web Path: Preparation

Prudent preparation of the web path is imperative before web guide system installation. Eradicate debris, obstructions, and vibration sources from the route. A clear and unhindered web path curbs the risk of material breakage and tracking discrepancies.

Thoroughly inspect rollers, pulleys, and other web path constituents for signs of wear or damage. Exchange worn elements to guarantee uninterrupted web movement. Additionally, sanitizing the web path from dust, grime, or residues orchestrates a conducive environment, unfettered by hindrances.

Strategic Sensor Placement: Enabling Optimal Performance

Sensor placement in the installation and calibration of web guide control systems stands as a linchpin. These sensors vigilantly oversee web material's alignment and location, enabling the system to effectuate requisite adjustments for precise tracking. Here are pivotal guidelines governing sensor placement:

Proximity to the Web Material

Plant the sensors in close proximity to the web material, refraining from physical contact. This tactic assures sensors discern the material's alignment and location with utmost precision. Too great a distance can impede effective tracking, leading to inaccuracies.

Alignment Par Excellence

Orchestrate sensor alignment congruent to the web path. Parallelism empowers sensors to accurately monitor web material movement. Misalignment could spawn erroneous readings, jeopardizing the system's tracking efficiency. Precision leveling tools ascertain optimal alignment.

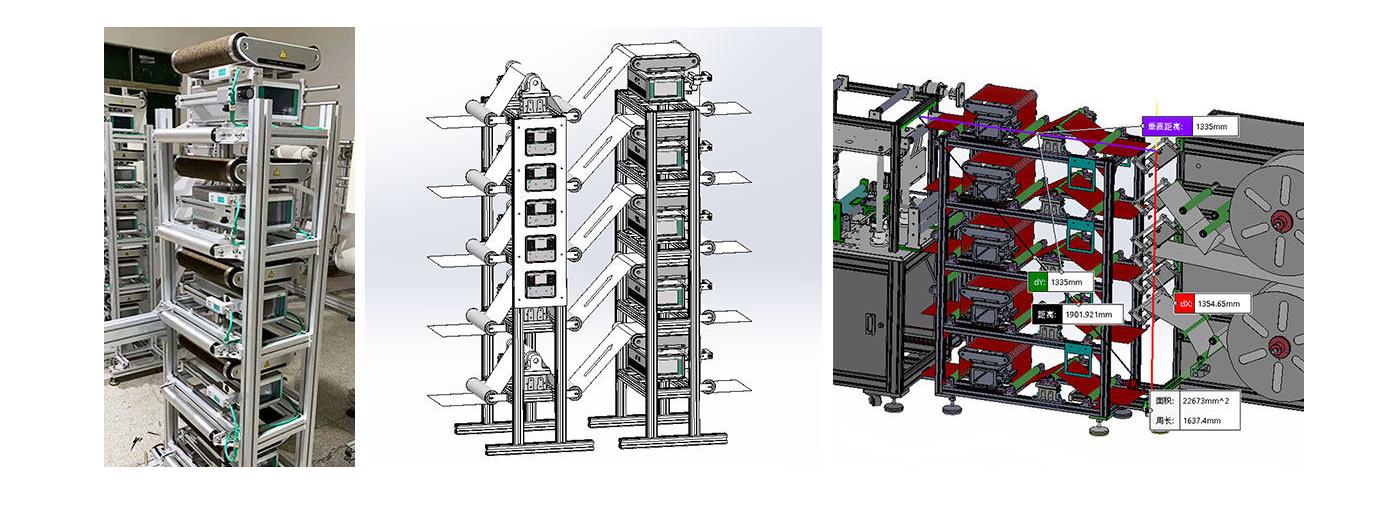

A Multitude of Sensors

Depending on the complexity of the web path and desired tracking precision, multiple sensors may prove requisite. Placing sensors at strategic junctures along the web path confers a comprehensive perspective of the material's position and alignment. This fortifies the system's capacity for exact adjustments, culminating in superior tracking performance.

Stability is Paramount

Secure sensors firmly to quell movement or vibration during operation. Loose or unstable sensors beget erroneous readings and tracking glitches. Leveraging manufacturer-prescribed mounting brackets or fixtures is indispensable for ensuring stability.

Meticulous Sensor Lighting Considerations

Pay heed to lighting conditions in the installation locale. Excessive glare, shadows, or light fluctuations impede sensor efficacy. Shield sensors from direct sunlight or potent light sources that can impede precise web material detection.

Navigating the Calibration Odyssey

Calibration emerges as the linchpin of web guide systems, harmonizing system parameters with online material to attain impeccable tracking. Calibration epitomizes the process through which the system attunes its alignment mechanisms. The calibration process follows a systematic course:

Harvesting Pertinent Information

Collect essential data concerning web material attributes and specific production prerequisites preceding calibration initiation. This entails factors like web width, desired alignment precision, and web speed. Manufacturer stipulations and recommendations form a vital compass during this phase.

Steering System Configuration

Leverage the system's control interface or software to configure parameters. Input critical information such as web width, speed, and alignment precision objectives. This control interface might encompass options for refining sensor sensitivity, control responsiveness, or other system-relevant parameters.

Test Run: A Crucial Litmus Test

Initiate a test run with a sample web material to gauge initial performance. Monitor how the system tracks the material's course and assesses alignment preservation. Scrutinize any anomalies or deviations from the expected trajectory during this trial.

Fine-Tuning Iterations: Precision in Progress

Tailor system parameters based on outcomes from the initial test run to elevate tracking accuracy. Fine-tuning encompasses sensor sensitivity, control response times, or filtering settings, contingent on the system's specifics. Iterations of these refinements shall vary based on the system's nuances and capabilities.

Perpetual Test Iterations

Upon effecting necessary adjustments, rerun the test with the sample web material. Evaluate the system's tracking prowess against desired alignment benchmarks. Persist in refining parameters and repeating test iterations until attaining the desired tracking precision.

Ultimate Fine-Tuning: Elevating Excellence

Consider supplementary fine-tuning avenues post-precise tracking achievement. This might encompass optimizing tension control mechanisms, edge detection settings, stability controls, or other system-specific components. Manufacturer literature or expert consultation stands as the guiding light for this phase.

Safeguarding Sustained Brilliance: Post-Installation Vigilance

Beyond the successful installation and calibration, ongoing vigilance and maintenance hold the reins for sustained performance. Instating a proactive maintenance regimen entails regular assessment and cleansing of system sensors, rollers, and other elements. Routinely scrutinize for signs of wear, misalignment, or any issues that could undermine system prowess.

Amid production runs, monitor system performance for deviations or tracking anomalies. Scrutinize performance metrics and undertake suitable adjustments through the control interface or software. Swiftly address emerging issues to curtail downtime and assure product consistency.

Summary

In the synthesis of web guide system installation and calibration lies the key to impeccable web tracking and unfaltering manufacturing operation. By adhering to the outlined best practices, you sidestep tracking discrepancies, minimize downtime, and fortify productivity. Pledge allegiance to manufacturer guidelines and seek expertise if necessary. With a meticulously installed and calibrated web guide system, your operations attain optimal efficiency, consistently delivering products of the highest caliber.

Comments (0)