Refractive index measurement stands as a straightforward and precise technique for assessing the purity of organic compounds. In numerous binary systems, a definitive correlation exists between the refractive index and composition, making it a valuable parameter for composition analysis. The refractive index is a vital optical property of transparent materials, particularly when it falls within the range of 1.30 to 1.70. In this range, the total reflection method becomes advantageous due to its convenience, rapid operation, minimal environmental requirements, and the absence of a necessity for a monochromatic light source.

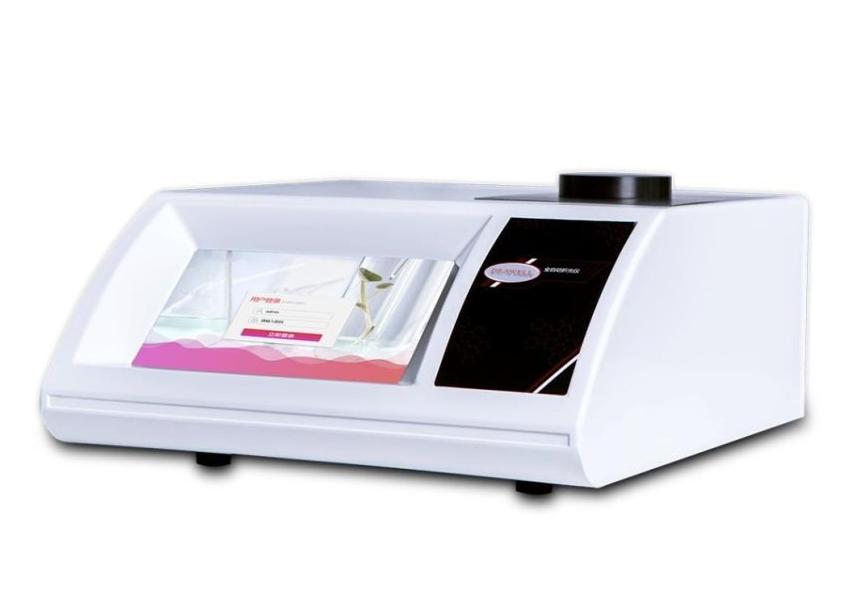

The refractometer, constructed using the total reflection method, serves as a specialized instrument for gauging the refractive index of transparent or translucent liquids. The utilization of an automatic refractometer to ascertain liquid composition is a prevalent technique in petrochemical, light industrial food, and other production and scientific research fields.

Functions of the Light Meter

Multilingual Interface and Data Output: Equipped with a full-color touch screen and a robust processor, the light meter offers menus in multiple languages. It facilitates data output via RS232, USB, and Bluetooth, enabling connections to computers, printers, and auxiliary devices like barcode readers.

Versatile Measurement Items: The LED touch screen allows users to switch between 16 different measurement parameters, including Refractive Index, Brix, Temperature Corrected Refractive Index, Temperature Corrected Brix, Zeiss, Butyric Acid, HFCS (42), HFCS (55), Urine Liquid SG, Osler, Baume, Babo, sodium chloride, and more (additional measurement items can be programmed as needed).

Temperature Control and Modes: The temperature-controlled refractometer offers four measurement modes: continuous mode (updated every 2 seconds), single scan mode (initiated after stabilization), automatic printing mode, and stable mode (based on user-defined fluctuation range for improved accuracy).

User-Friendly Data Input: Users can opt for keyboard or numeric keyboard input. When printing, the refractometer sends the instrument's time, date, and serial code along with the print data to the printer.

Advanced Data Analysis: The refractometer allows users to set upper and lower alarm limits, calculate average values, read standard deviations, and view real-time data curves.

Proper Usage of a Refractometer

Initial Calibration: Before commencing measurements, verify the readings using distilled water or a standard sample. To use a standard sample, apply 1-2 drops of bromonaphthalene to the polished prism surface and affix it to the refractive prism. Ensure that the reading field of view matches the value on the standard sample, and check if the boundary image aligns with the center of the reticle. If not, gently adjust the animal lens using a screwdriver until the image aligns correctly. This minimizes initial errors, including operator aiming errors.

Calibration and Consistency: Once calibrated, refrain from moving this part during subsequent measurements. Routine measurement typically does not require instrument recalibration. If any doubts arise about the refractive index indication, check for initial errors and correct them.

Regular Maintenance: Before each measurement and calibration, gently clean the rough surface of the incident prism, the polished surface of the refractive prism, the polished surface of the standard sample (1:1), and absorbent cotton with anhydrous ethanol mixture. This prevents the presence of contaminants that could affect imaging clarity and measurement precision.

Refractometer Maintenance

Storage: Store the instrument in a dry and well-ventilated room to prevent mold growth on optical components caused by humidity.

Cleaning: Promptly clean the instrument, including optical parts, metal components, and painted surfaces, when exposed to corrosive liquids. Always clean the instrument after use.

Sample Quality: Ensure that tested samples are free from hard impurities. When analyzing solid samples, take precautions to protect the refractive prism's surface from roughness or indentation.

Cleanliness: Maintain the refractometer's cleanliness by avoiding contact with greasy or sweaty hands. In case of dust on optical surfaces, gently wipe it with high-grade deerskin or long-fiber absorbent cotton, and blow it away using a gentle stream of air. For oil stains on optical components, promptly wipe them with alcohol.

Avoid Vibration: Prevent strong vibrations or shocks to the refractometer, as they can damage its components and compromise measurement accuracy.

Comments (0)