01 Introduction

Since its advent in the 1960s, laser technology has rapidly developed into a key tool in industrial manufacturing due to its high energy density, excellent directionality, and controllability. Compared to traditional mechanical processing methods, laser processing offers significant advantages such as non-contact, high precision, and a high degree of automation. It is widely used in industrial manufacturing for material cutting, welding, marking, drilling, and additive manufacturing. Based on the type of laser and its process characteristics, industrial laser processing is primarily categorized into three main types: laser cutting, laser welding, and laser additive manufacturing. Each process has its own unique mechanism of action and scope of application.

02Laser Cutting

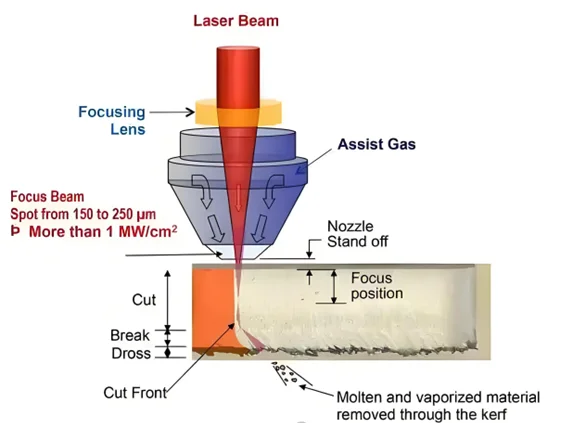

Laser cutting is one of the most mature industrial laser applications. It utilizes a high-power laser beam to melt and vaporize the material, accompanied by an assist gas to blow away the slag, achieving efficient and precise cutting. CO₂ lasers and fiber lasers are currently the mainstream equipment, suitable for cutting medium-thin plates in materials such as carbon steel, stainless steel, and aluminum alloys. This technology offers advantages such as narrow kerfs, minimal heat-affected zones, the absence of molds, and the ability to quickly change processing paths. It is particularly well-suited for demanding industries such as automotive manufacturing, sheet metal processing, and aerospace.

(1) In automotive manufacturing, laser cutting is used to produce a variety of components from body panels to engines. For example, fiber lasers are used to cut high-strength steel parts with high precision, thereby achieving lightweighting of automobiles.

(2) The aerospace industry has also benefited from laser cutting technology, especially in the production of complex components made of advanced materials such as titanium and composites. For example, ultrafast lasers can be used to cut complex-shaped titanium alloy components while minimizing thermal damage and ensuring the structural integrity of the components, significantly improving the performance and safety of aerospace components.

Figure 1. Laser cutting principle diagram

03Laser welding

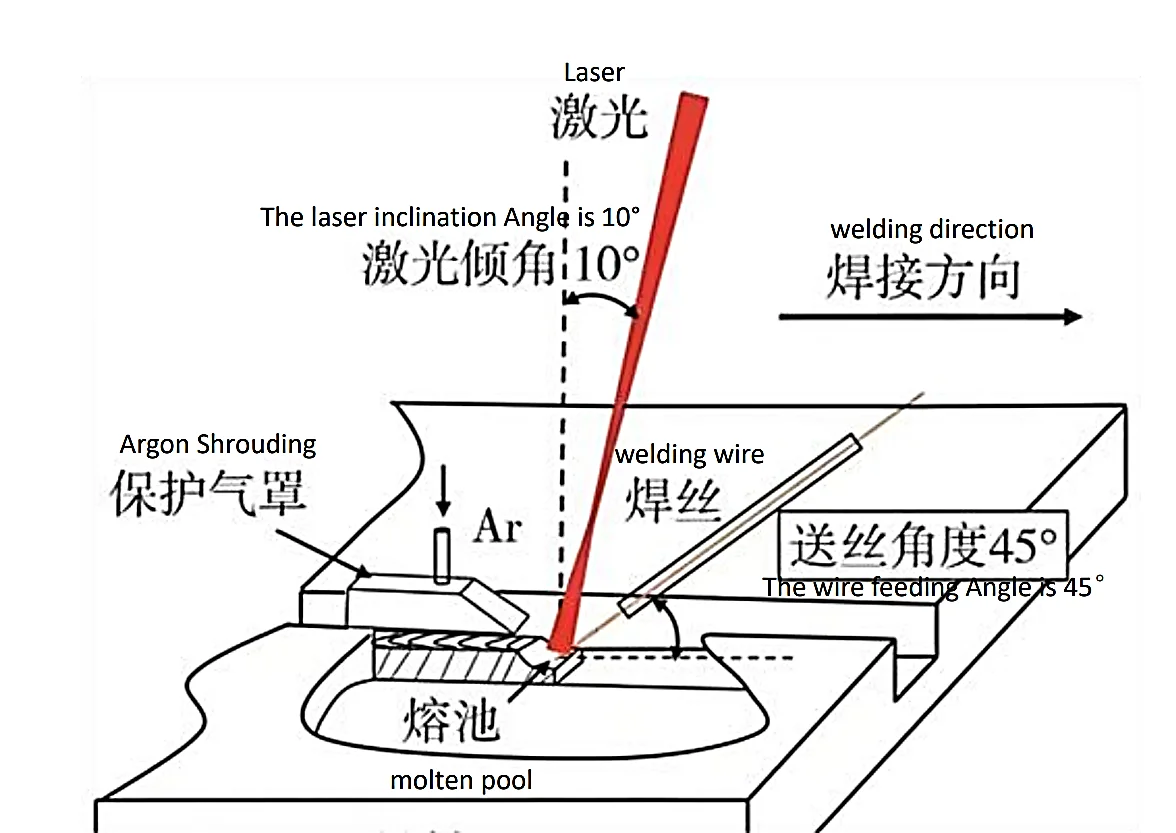

Laser welding relies on a laser beam to melt metal materials at high speed, achieving connections. It boasts deep penetration, high speed, and low heat input. Common welding modes include continuous laser welding and pulsed laser welding, which are suitable for precision welding of thin plates and deep penetration welding. Compared to arc welding, laser welds offer higher strength and less deformation, making them suitable for applications such as power battery packaging, stainless steel device welding, and nuclear power structural component manufacturing. Laser welding has become a mainstream connection method, particularly in battery manufacturing.

(1) In the automotive industry, laser welding is used to join body panels, engine components, and other critical parts. For example, fiber lasers are used to weld high-strength steel parts with high precision, creating strong and durable joints.

(2) Electronics Industry In the electronics industry, laser welding is used to connect small and delicate components with high precision. For example, diode lasers are used to weld cells in lithium-ion batteries to ensure the reliability of electrical connections.

(3) In the aerospace industry, the Boeing 787 Dreamliner uses laser welding technology to connect titanium alloys and composite materials, which greatly reduces the number of rivets, reduces the weight of the fuselage, and improves fuel efficiency.

Figure 2. Schematic diagram of laser welding with filler wire

04Laser Additive Manufacturing

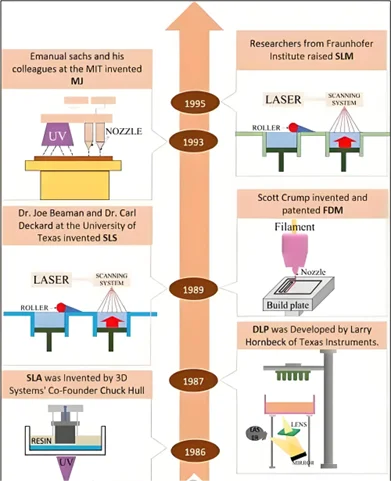

Laser additive manufacturing (also known as laser 3D printing) achieves the layer-by-layer buildup of complex structures by melting powder or filaments layer by layer, representing a shift in manufacturing from "subtractive" to "additive." Laser-based additive manufacturing processes, such as selective laser melting and direct metal deposition, are capable of producing complex metal parts with high precision and strength. Compared to traditional machining, laser additive manufacturing can achieve integrated molding and lightweight design of complex structures while maintaining material strength.

(1) In automobile manufacturing, the titanium alloy parts of Ferrari F1 racing cars are manufactured using laser additive manufacturing technology, which improves the heat resistance and strength of the parts and optimizes the aerodynamic design of the racing car.

(2) Medical Industry In the medical industry, laser-based additive manufacturing is used to produce customized implants and prostheses.

(3) In the aerospace industry, laser-based additive manufacturing is used to produce complex components such as turbine blades and fuel nozzles.

Figure 3. Development history of 3D printing technology.

05Conclusion

As a crucial enabler of advanced manufacturing, laser technology is continuously expanding its industrial applications. Currently, laser processing is also evolving toward higher power, higher precision, and multi-process integration, such as laser-arc hybrid welding, laser ultrafast micromachining, and intelligent laser monitoring systems. In the future, with the continued advancement of high-power semiconductor lasers, intelligent control systems, and green manufacturing concepts, laser processing will continue to play a key role in intelligent manufacturing, personalized products, and the processing of extreme materials.

https://www.y-crystaled.net/application-of-laser-in-industry.html

Comments (0)