In the world of industrial manufacturing, durability, cost-efficiency, and corrosion resistance define material excellence. Among the many metallic solutions available, galvanized coil sheets have become a cornerstone for modern engineering and infrastructure projects. Whether applied in automotive production, building construction, or appliance fabrication, galvanized coil sheets deliver the ideal combination of strength, longevity, and aesthetics. At Baichuan Energy, precision technology and rigorous quality control ensure that every sheet performs at the highest standard for global customers.

1. The Science Behind Galvanized Coil Sheets

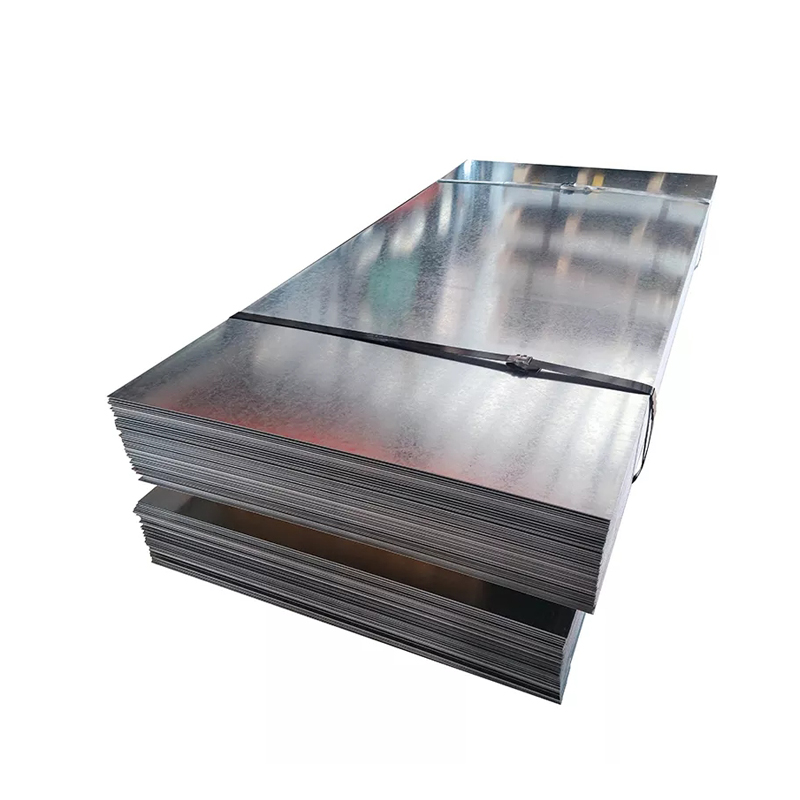

A galvanized coil sheet is a steel sheet coated with a layer of zinc to protect it from rust and corrosion. This process, typically achieved through hot-dip galvanization, forms a metallurgical bond between zinc and steel, ensuring a durable protective layer that resists oxidation even in harsh environments.

The zinc coating acts as both a physical barrier and a sacrificial anode, meaning that even if the coating is scratched, zinc continues to protect the exposed steel. This electrochemical protection is the key to the material’s superior corrosion resistance, which makes galvanized sheets suitable for outdoor and marine applications.

2. Why Galvanized Coil Sheets Are Critical for Modern Industries

In today’s competitive industrial landscape, every component must balance cost, performance, and sustainability. Galvanized coil sheets achieve this balance in ways few materials can:

-

Superior Corrosion Resistance: The zinc coating significantly extends the steel’s lifespan, minimizing maintenance and replacement costs.

-

High Strength-to-Weight Ratio: Ideal for structural and automotive use, where durability must coexist with weight efficiency.

-

Excellent Surface Finish: Smooth and uniform coating suitable for painting or powder coating, meeting the needs of manufacturers that value both function and appearance.

-

Sustainability: Galvanized steel is 100% recyclable and aligns with global environmental standards for sustainable construction and production.

At Baichuan Energy, each coil undergoes precise surface treatment, strict mechanical testing, and controlled galvanization processes to ensure uniform zinc adhesion and coating thickness. This level of precision allows Baichuan Energy’s galvanized coil sheets to perform consistently in demanding environments such as coastal regions, factories, and infrastructure sites.

3. Advanced Production Capabilities at Baichuan Energy

Baichuan Energy employs advanced continuous galvanizing lines equipped with automated control systems that monitor coating weight, temperature, and line speed in real time. The company’s production facilities are capable of handling a wide range of specifications — from 0.12mm thin coils for lightweight appliances to 6.0mm heavy-duty sheets for industrial structures.

Baichuan Energy’s galvanizing technology ensures:

-

Uniform Coating Thickness with ±5% accuracy

-

Optimized Surface Adhesion for post-processing like cutting, stamping, or forming

-

Improved Flatness and Edge Control to meet precise dimensional tolerances

The company’s technical expertise also extends to specialized coatings such as galvalume (zinc-aluminum alloy) and zinc-nickel composite coatings for customers seeking enhanced thermal or chemical resistance.

4. Applications Across Industries

Galvanized coil sheets serve as foundational materials in multiple sectors:

-

Construction: Used in roofing panels, wall claddings, gutters, and structural frames due to their resistance to weathering and corrosion.

-

Automotive: Integral to car bodies, chassis, and undercarriages that require long-term corrosion protection.

-

Appliances: Common in the manufacture of refrigerators, washing machines, and HVAC systems for their clean finish and longevity.

-

Agricultural Equipment: Used in barns, silos, and irrigation systems to ensure performance in outdoor conditions.

Baichuan Energy’s customers range from large-scale builders to global appliance manufacturers, all of whom rely on the company’s galvanized sheets for consistent performance and reliability.

5. Innovation and Sustainability: The Future of Galvanized Materials

The future of galvanized coil sheet production lies in eco-efficiency and smart manufacturing. Baichuan Energy is integrating green galvanizing technologies that reduce zinc waste, lower emissions, and enhance recyclability. Through continuous R&D, Baichuan Energy also develops high-performance coatings that improve heat reflection, energy efficiency, and surface durability.

By combining innovation with sustainability, Baichuan Energy not only strengthens its position in the global steel market but also contributes to a more energy-conscious industrial ecosystem.

6. Conclusion

Galvanized coil sheets are more than just coated steel — they are the structural foundation of modern progress. With decades of expertise, Baichuan Energy continues to lead the industry by delivering galvanized materials that set new benchmarks in performance, precision, and environmental responsibility. Whether your project demands architectural beauty or industrial resilience, Baichuan Energy’s galvanized coil sheets offer the reliability and value your business can depend on.

Comments (0)