In a world driven by precision and performance, the smallest imperfection can lead to significant consequences. This is especially true in industries like pharmaceuticals, food, and chemical manufacturing, where even microscopic leaks can compromise product integrity and consumer safety. That’s where the Micropore Leak Inspector by SANTUO comes in — a cutting-edge innovation designed to identify the invisible and ensure the highest standards of reliability.

As a technology pioneer, SANTUO integrates mechanical, electrical, software, and visual technology to create intelligent automation equipment that is efficient, stable, and cost-effective. The company’s Micropore Leak Inspector is the perfect embodiment of this philosophy — replacing manual inspection with automated precision and human eyes with advanced machine vision to achieve consistent, data-driven quality assurance.

1. The Importance of Micropore Leak Detection in Modern Manufacturing

Leak detection plays a crucial role in ensuring product safety and regulatory compliance. In high-value industries such as pharmaceuticals, food, daily chemicals, and fine chemicals, even a tiny micropore can lead to contamination, oxidation, or product failure. Traditional inspection methods, often reliant on human observation, are no longer sufficient to detect these minute defects.

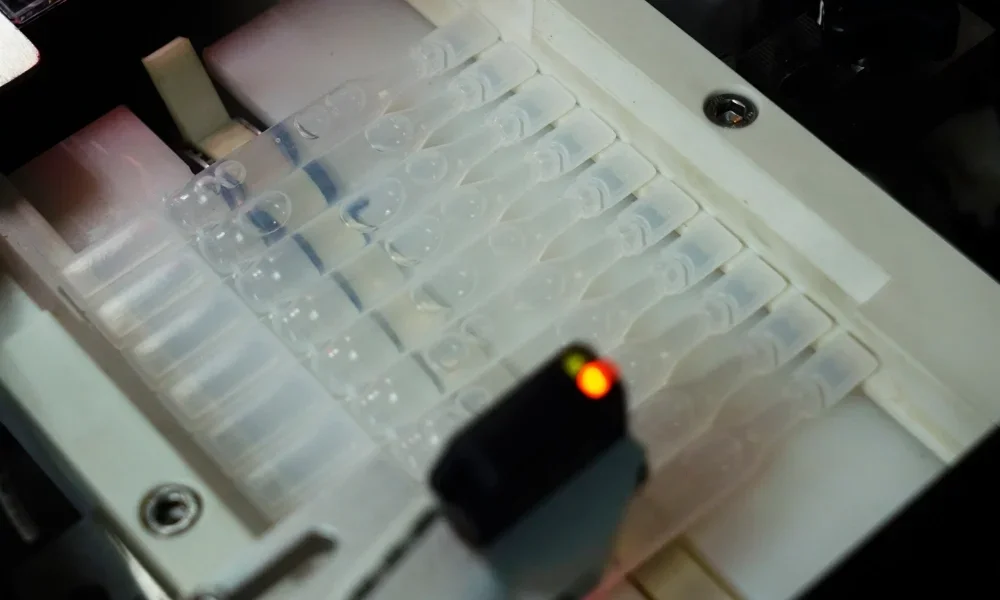

The SANTUO Micropore Leak Inspector revolutionizes this process by detecting ultra-small leaks that are invisible to the naked eye. Through the integration of machine vision and automated control, it offers unmatched precision and reliability — ensuring that every package, container, or component meets stringent international quality standards.

2. SANTUO’s Integrated Technology Advantage

What sets SANTUO apart is its ability to merge multiple disciplines — mechanical design, electrical systems, intelligent software, and visual inspection — into one cohesive solution. The Micropore Leak Inspector is built around this integrated engineering strength, enabling:

-

High-Speed Automation: Automated leak detection significantly reduces human involvement, replacing manual inspection with consistent, accurate, and repeatable performance.

-

Energy Efficiency: Designed with intelligent power management systems, it minimizes energy consumption without compromising testing accuracy.

-

Machine Vision Integration: Advanced cameras and algorithms simulate the sensitivity of the human eye but with higher resolution and zero fatigue, capable of detecting micro-level defects.

-

Customizable Software Systems: The control software allows users to configure test parameters, record data, and adapt to various packaging materials and production line speeds.

Through this multidimensional approach, SANTUO ensures that the Micropore Leak Inspector not only performs flawlessly but also integrates seamlessly into existing production lines, enhancing overall operational efficiency.

3. Applications Across Multiple Industries

The versatility of the SANTUO Micropore Leak Inspector makes it indispensable across a range of industries:

-

Pharmaceuticals: Ensures the integrity of stick packs, BFS packs, and IV bags, preventing contamination and ensuring sterility.

-

Food and Beverage: Verifies airtight sealing of pouches, bottles, and vacuum packaging to maintain freshness and safety.

-

Daily Chemical Products: Detects micro-leaks in cosmetic containers, cleaning products, and aerosol packaging, preventing leakage and product waste.

-

Chemical and Industrial Applications: Tests for tightness in small-scale chemical containers, ensuring safety in transport and storage.

Each of these applications highlights the growing demand for automated, precise leak detection as part of a comprehensive quality control strategy.

4. Smart Automation for Cost Reduction and Efficiency

SANTUO’s mission extends beyond developing advanced inspection tools — it’s about transforming production itself. By replacing human inspection with intelligent automation, the Micropore Leak Inspector reduces production costs, minimizes labor dependency, and enhances consistency.

-

Reduced Human Error: Machine vision and automated algorithms ensure that every product is tested under the same conditions, eliminating subjectivity.

-

Higher Productivity: High-speed testing capabilities allow for large-scale inspection without slowing down production lines.

-

Lower Operational Costs: The energy-saving design minimizes power consumption while maximizing throughput.

-

Data-Driven Insights: Integrated software collects and analyzes production data, enabling predictive maintenance and process optimization.

These advantages reflect SANTUO’s philosophy: to build intelligent, people-saving, and energy-saving production solutions that align with the future of smart manufacturing.

Conclusion: Precision You Can Trust

The SANTUO Micropore Leak Inspector embodies the company’s dedication to innovation, efficiency, and reliability. By uncovering the invisible, it enables manufacturers to achieve higher standards of product quality, lower operational costs, and greater production stability.

In industries where precision defines reputation, SANTUO’s advanced inspection technology provides more than just a testing solution — it provides confidence, efficiency, and the future of intelligent manufacturing.

https://www.santuomachine.com/how-micropore-leak-inspectors-guarantee-product-reliability.html

Comments (0)